In the construction industry, maximizing the utilization of forest products is essential for sustainability and efficiency. At Parallel Lumber Group, we pride ourselves on our innovative approach to utilizing wood resources effectively, particularly through the production of finger joint studs. Read on to explore how finger joint studs play a crucial role in optimizing the utilization of forest products and why they’re a sustainable choice for construction projects.

The Innovation of Finger Joint Studs

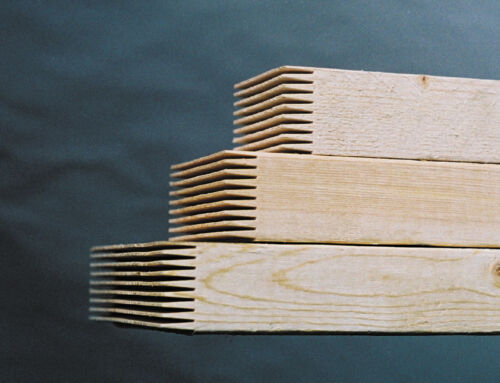

Finger joint studs are engineered wood products crafted from shorter pieces of lumber that are joined together using a finger jointing technique. This innovative process allows us to create longer, straighter, and more stable studs compared to traditional solid-sawn lumber. By joining shorter pieces of wood, we can make the most of available timber resources and minimize waste.

Maximizing Resource Efficiency

One of the primary advantages of finger joint studs is their ability to maximize the utilization of forest products. By utilizing shorter pieces of lumber that would otherwise be discarded or used for lower-value applications, we reduce waste and make more efficient use of available wood resources. This not only helps to conserve forests but also ensures that every part of the tree is utilized effectively.

Sustainable Manufacturing Practices

At Parallel Lumber Group, we are committed to sustainable manufacturing practices throughout the production process of finger joint studs. We source our lumber from responsibly managed forests and adhere to strict environmental standards to minimize our impact on the environment. Additionally, our finger jointing process is designed to optimize material usage and reduce energy consumption, further enhancing the sustainability of our products.

Environmental Benefits of Finger Joint Studs

Finger joint studs offer several environmental benefits compared to traditional solid-sawn lumber:

Reduced Waste

By utilizing shorter pieces of lumber, finger joint studs help to minimize waste in the manufacturing process and reduce the amount of wood sent to landfills.

Enhanced Resource Efficiency

The finger jointing process allows us to make more efficient use of available timber resources, reducing the need for harvesting new trees and promoting sustainable forestry practices.

Improved Sustainability

With their durability, stability, and efficient use of resources, finger joint studs contribute to more sustainable construction practices and help to mitigate the environmental impact of building projects.

Choose Parallel Lumber Group for Sustainable Building Solutions

Parallel Lumber Group is your trusted partner for sustainable building solutions. Our finger joint studs are engineered to optimize the utilization of forest products while delivering superior performance and reliability in construction projects. Contact us today to learn more about how our products can enhance the sustainability of your next building project.